Cutting Force Dynamometer

Piezo-Electric Based Cutting Force Dynamometer

Introduction

Metal machining processes are characterized mainly by quick changes in quantified elements. Individual changes do not occur in isolation and they influence each other. The analysis of these changes require study of the complicated systems in their real situation. The study of cutting processes such as turning and facing,from dynamic aspects, is very important. The trend towards the measurement of cutting forces in machining leads to many theoretical and practical problems. Theoretical problems associate mainly with the choice of a suitable technique to measure, and the statistical methods to analyze the components of cutting force to be determines in real time. Practical problems involve the errors and uncertainties relating to the measurement systems used.

It is not possible to measure directly the cutting forces and their amplitudes at their real origin. The measuring devices selected for experiments should be independent of forces and associated movements at the point of application, so that the components of a general force vector can be measured as a reaction of the cutting edge in a defined plane distant from the cutting edge.

It is generally known that the accuracy of the cutting force measurement is closely dependent on the quality and sensitivity of the measurement device used. There are also effects of interactive factors associated with the static stiffness of joints in the machine tool work piece systems.

In order to obtain true measurements, it should be critically considered if the data, obtained within the limitations of the measuring and evaluating technique used, is repeatable and accurate.

(1) Error of the measurement: any departure from an accepted standard due to imperfection in any part of the measurement system.

(2) Accuracy: The closeness of readings to a accepted standard.

(3) Precision: The repeatability of individual readings about their real value.

(4) Repeatability: The closeness between a number of measurement made at the same time.

(5) Reliability: Confidence in a measurement affected by uncontrollable random factors.

(6) Reproducibility: The closeness of measurement of the same quantity obtained at different times.

(7) Scatter: The deviation from a real value of precise readings.

Piezoelectric dynamometer is a piezoelectric crystal sensor weili cutting force dynamometer. When the quartz crystal deformation occurs because of external force, in some of its different number appears on the surface polarization charge. This is the role of the electric field, but due to strain or stress generated within the crystal electrodes of the phenomenon known as the piezoelectric effect. Produced by measuring the amount of the charge that can achieve the purpose of cutting force measurements.

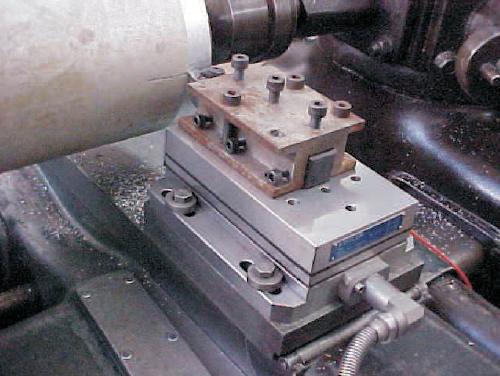

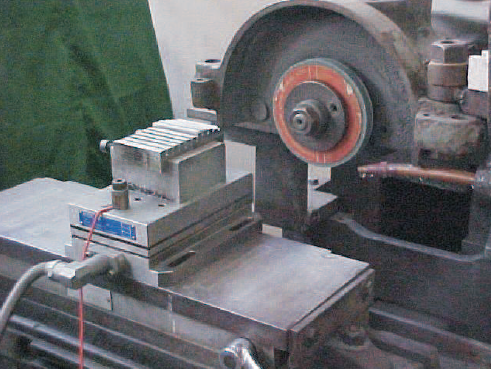

The dynamometer consists of a 3 component force sensors molded between a base plate and cover plate.As piezo sensors are used so force components are measured practically without displacement.

The dynamometer is corrosion-resistant with used of high grade stainless steel cover and protected against spray water and cutting fluids.(IP67 Sealing)

The sensors are thermally isolated with a special thermal insulation layer which makes the dynamometer largely insensitive to temperature influences.

Applications:

- For measuring cutting forces in milling, grinding and turning

- Reliable force measurement system

- Ultra precision machining

- High speed machining

- High precision hard turning

- Wafer cutting.

Features:

- Low thermal error

- High rigidity

- High natural frequencies

- Low threshold

- low profile design

Technical Data:

Measuring components: Multi Components (Three orthogonal components Fx,Fy, Fz)

Shear Force Range: -15 to +15kN

Vertical Forces: 0 to 30kN

Sensitivity: -6 to -9 pC/N

-2 to -4 pC/N

Sampling Rate: 10KHz or more

Linearity: <+0.5

Hysteresis: <0.5

Cross sensitivity: <+2

Rigidity Cx, Cy, Cz: 0.6 to 0.9, 0.6 to 0.9, 2 to 3 kn/micro ohm

Capacitances: 400-600 pf

Operating temperature: 0-60 degree celsius

Insulation Resistance: >10 Mega Ohms

Ground Insulation: >10 Mega Ohms

Weight: 25kg (max)

Standard Accessories:

- Cover

- Mounting Screws

- Connector

- Connecting cable

Optional Accessories:

- Tool Holder

- Charge Amplifier

- Data Logger