Solid Flow Meter

Solid Flow Meter

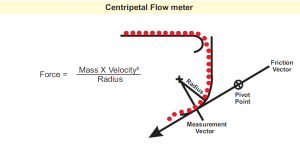

Centripetal Flow Meters

(MFM-C)

Our Centripetal Flow Meter model MFM-C is a solid Particle Mass Flow Meter, that is durable, accurate, maintenance free, compact, and cost effective. It is unique and positioned to replace weigh belts, impact meters, loss in weight meters and static weighing scales, where accuracy, low maintenance and zero drift is paramount.

Food Grains

Accuracy is not affected by change in product density, elasticity or shape. The meter offers a typical accuracy of +/-0.25% of full scale reading at calibrated flow rate and is repeatable within +/-0.1%. Our MFM-C centripetal flow meter has no moving parts. Calibration and installation are simple to perform.

Solid Construction / Low maintenance/ sturdy high grade aluminum / steel alloy construction with stainless steel flow paths makes the MFM-C a very low maintenance instrument. It rarely requires re-calibration because there are no moving parts. There are no belts or drives which need timely replacement. Plus, the electronics are location outside the process stream and are not subject to vibration from the manufacturing process.

Totalizing Applications Include:

- On line Batching

- Filling

- Inventory Control

The flow control output is a real time output that can govern the flow rate controlling VFD drive or a valve with an analogue signal allows the operator to adjust variables in the process to keep flow at the required output. For example, the flow control application can allow the feeding of an extruder at a constant rate by controlling the flow rate through the rotary valve.

Flow Control Application Include:

- Ratio control of two or more products streams.

- Extruder feed control

- Continuous flow rate.

Flexible

Our MFM-C flow meter is not affected by changes in product elasticity, density, shape or friction. Fluctuations in flow rate dont impact its accuracy. The linearity of the zero friction formula gives the Solid Flow Meter its ability to measure at various densities and turn down ratio while maintaining near perfect accuracy.

Trundown Ratio

Our MFM-C Flow meter has a minimum 15:1 turndown capability while maintaining accuracy. The meter’s unique design enables it to identify and cancel the friction component of the mass flow. The resulting signal is Flow=Mass Rate, which is linear. The linearity allows the meter to work at 0.25% accuracy at full scale. This means it is now affected by the wide variations typical to process flow.

Technical Specifications:

Power Supply: 220VAC/ 50Hz

operating Temperature Range (Sensor): 0-80/0-150/0-250 Degree Celsius

operating Temperature Range (Digitizer): 0-50 Degree Celsius

Flow Material: Powder, Granules, Grains and any flowable material

Typical Capacity: 20kg – 1000 TPH

Inlet Size: 25-1250mm

Outlet Size:25-1250mm

Accuracy: +/-0.1%